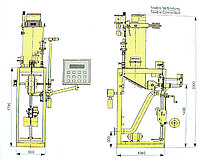

Pneumatic packer HSP 50

Developed by Natronag bagging machine is characterized by its modular design.

Special inlet valve, e. g. for abrasive or very coarse-grained bulk materials enable a trouble-free, safe operation of bagging machine also under most adverse circumstances.

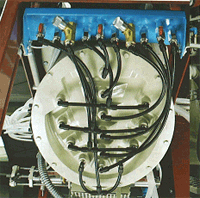

The tailored to the respective bulk material, aeration bottom ensures optimal fluidization of the medium. Maximum mass registration at the lowest possible air entry is the strength of the bagging machine.

With the homogeneous, globally patented 14- chamber bottom an optimal, material specific fluidization is possible within the aeration bottom.

Difficult flowing, mealy up to fine-grained products, are bagged with a minimum air consumption up to 350 b/h at 25kg.

Various designs

Are versions of bagging it for:

Manual bagging

That means application of the empty bags by hand, and release of the full bag manually or by a vertical bag rejector arranged in front of the machine over a conveyor.

Automatic Bagging

That means ta combination of a bagging machine with an empty bag applicator and/or Bag sealing unit.

This bagging machine can be used as single or series machine - equipped with all levels of automation.